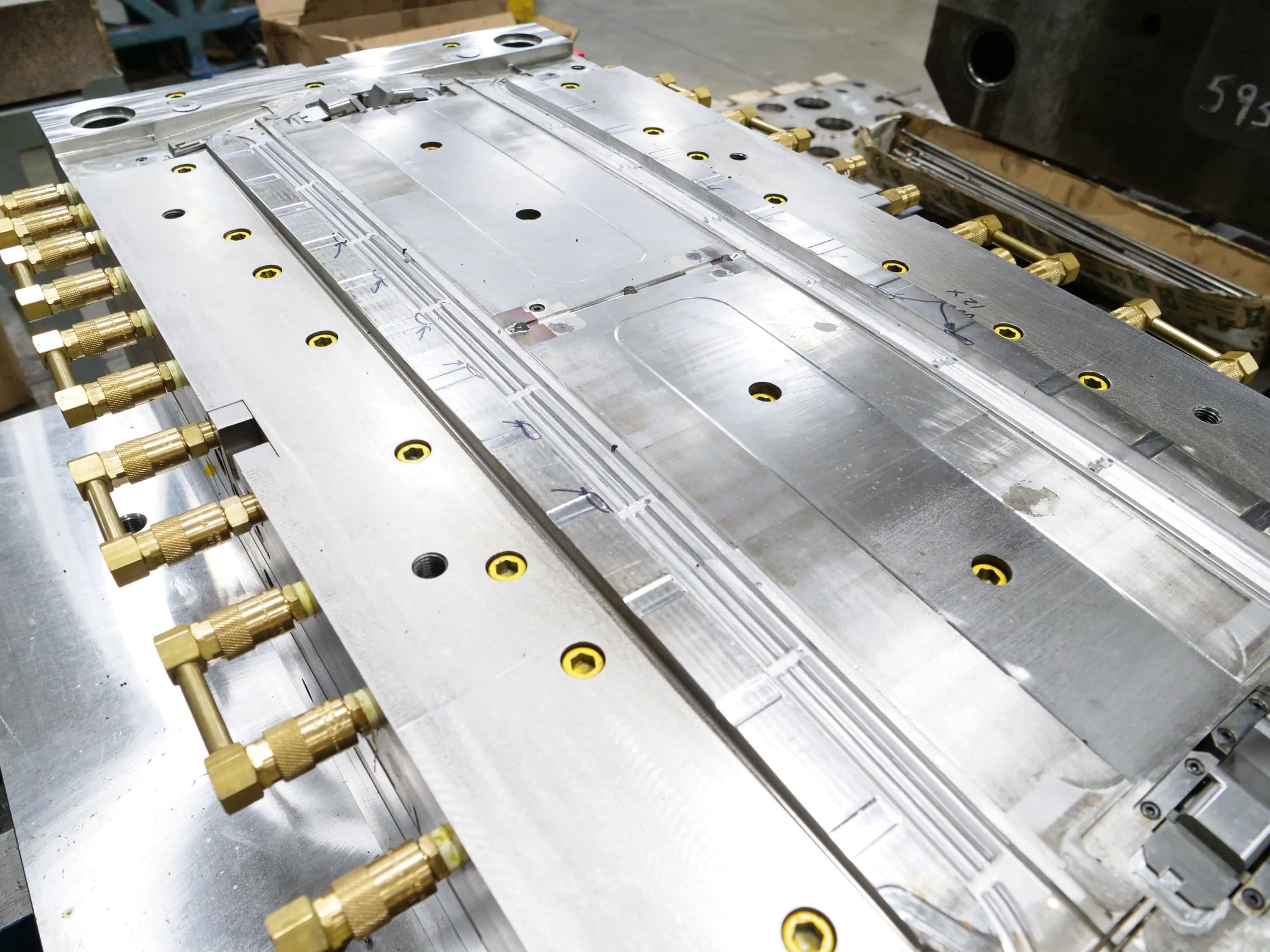

As a source of innovative design solutions and outstanding quality, HELLEBUSCH has earned a reputation for building tools that work the first time, are delivered on-time, and are built at competitive prices. Simple or complex, large or small, HELLEBUSCH Tool and Die has the technical know-how to solve difficult problems, and the years of experience needed to design and build tools that perform under ‘real world’ molding conditions. Our tooling is designed to specifically meet your custom requirements, whether it is class 101 molds, prototypes or somewhere in between.

Our engineering and manufacturing capabilities include Multi cavitation, Family molds, Stack molds, Double shot rotary, Air injection, Over molding on stampings, die-cast parts or glass, Rubber molds, Thermosets, Unscrewing molds, stripper plate or three plate molds. We can team with your desired hot manifold supplier for a turnkey engineered solution whether it is multiple valve gates or a single hot drop, HTD can save you money by doing the plate work and assembly of hot manifolds in-house. We supply injection molds from 25 tons up to 3,000 tons of locking force, for a diverse list of customers in the automotive, utility, consumer products, industrial products, lawn & garden, aerospace & defense, appliance, lighting, and medical industries in the USA, Canada, and Mexico.